Understanding Camshaft Manufacturing: A Key to Diesel Engine Efficiency

The camshaft manufacture process is crucial for ensuring the optimal performance of diesel engines. As a key component in engine mechanics, the camshaft is responsible for regulating the timing of valve openings and closings. This article delves deep into the nuances of camshaft manufacture, exploring its impact on diesel engine efficiency, its manufacturing processes, and the benefits of quality camshaft production.

What is a Camshaft?

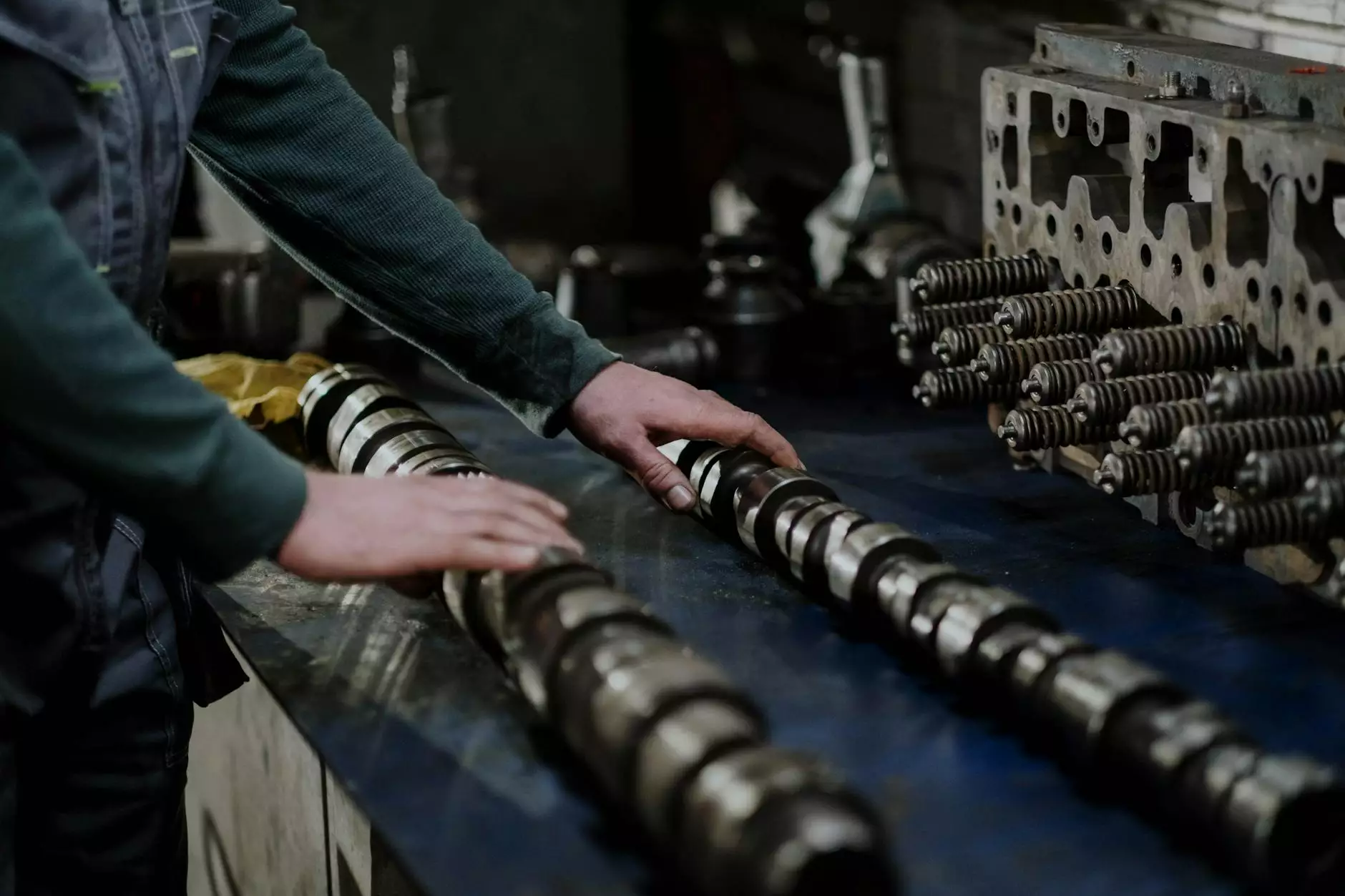

A camshaft is a rotating shaft that contains multiple cams (lobe-shaped profiles) that convert rotational motion into linear motion. In diesel engines, its primary function is to control the intake and exhaust valves. The timing and precision of these movements directly influence the engine’s performance and efficiency.

The Importance of Camshaft Manufacture in Diesel Engines

The camshaft manufacture process is integral to the overall performance of a diesel engine. Here are several reasons why a high-quality camshaft is essential:

- Precision Timing: A precisely manufactured camshaft ensures that valve openings and closings align perfectly with the engine cycle, enhancing engine efficiency.

- Durability: High-quality materials and precise engineering prevent wear and tear, leading to longer-lasting performance.

- Performance Optimization: A well-designed camshaft can enhance the power output and fuel efficiency of a diesel engine.

- Emission Control: Proper timing from a reliable camshaft can significantly reduce harmful emissions, meeting stringent regulations.

Key Elements in Camshaft Manufacture

Materials Used in Camshaft Production

The choice of materials in camshaft manufacture is critical. Commonly used materials include:

- Cast Iron: Known for its excellent wear resistance and strength, often used for its durability.

- Steel: Offers higher performance with less weight, enhancing engine responsiveness.

- Aluminum Alloys: Lightweight and excellent for high-performance applications but may require special coatings for durability.

The Manufacturing Process

The camshaft manufacture process typically involves the following steps:

- Design and Prototyping: Engineers design cam profiles using computer-aided design (CAD) software and develop prototypes for testing.

- Material Selection: Choosing the right material based on performance needs and cost considerations.

- Casting or Machining: Camshafts can be made through casting methods or precision machining, depending on the required specifications.

- Heat Treatment: Components are subjected to heat treatment processes to enhance hardness and wear resistance.

- Finishing Processes: Final touches include grinding and polishing to achieve precise dimensions and surface finishes.

Quality Control in Camshaft Manufacture

Quality control is imperative in the camshaft manufacture process. To ensure high standards, manufacturers implement various testing methods:

- Dimensional Verification: Each camshaft is checked for accurate dimensions to ensure compatibility with engine specifications.

- Material Testing: Rigorous tests to verify material properties such as tensile strength and hardness.

- Performance Testing: Real-world testing on diesel engines to ensure each camshaft meets performance standards.

Benefits of Investing in Quality Camshaft Manufacture

Investing in quality camshaft manufacture can yield significant benefits for businesses dealing with diesel engine parts:

- Enhanced Engine Efficiency: Well-manufactured camshafts lead to optimized fuel consumption and better overall engine performance.

- Competitive Advantage: Offering high-quality products can set a business apart in a competitive market.

- Customer Satisfaction: Durable and efficient camshaft components lead to lower customer complaints and enhanced satisfaction.

Future Trends in Camshaft Technology

The landscape of camshaft manufacture is continuously evolving. Here are some trends to watch for:

- Variable Valve Timing (VVT): Innovations in camshaft designs allow engines to adjust valve timing dynamically, improving efficiency.

- Advanced Materials: Development of new materials like light-weight composites can further enhance performance.

- Sustainability Initiatives: Manufacturers are increasingly focusing on sustainable production practices to minimize their environmental footprint.

Conclusion

In summary, the camshaft manufacture process is vital to the performance and efficiency of diesel engines. As businesses like client-diesel.com strive to provide quality diesel engine parts, understanding the intricacies of camshaft production is pivotal. By prioritizing precision, quality, and innovation, manufacturers can not only meet the demands of modern engines but also contribute positively to environmental sustainability.

Embracing advanced manufacturing technologies and quality control standards will ensure that businesses remain competitive in the ever-evolving automotive industry. It's essential for stakeholders to recognize the long-term benefits of investing in quality camshaft manufacture, leading to success and growth in the diesel engine parts market.